E-mail:

info@chalcoaluminum.com> 5356 aluminum wire for mig welder

| Physical Property | ||||

|

Density kg/dm3 |

Melting temperature ℃ |

Thermal conductivity w/m•K |

Linear expansion coefficient 10¯6/K(20-100℃) |

Electric conductivity % IACS |

| 2.65 | 575-633 | 120 | 24.1 | 29 |

| Weld Mechanical Properties (reference value) | ||

| Tension Strength(MPa) | Yield Strength(MPa) | Elongation (%) |

| 250--300 | 110--140 | 15--25 |

| ER5356 Aluminium & Aluminium Alloy welding wire | |

| Classification |

GB/T 10858-2008············ HS 331 AWS A5.10·············· ER 5356 |

|

Typical composition in % |

Si·················· <0.25 Fe·················· <0.40 Cu·················· <0.10 Mn················· 0.05—0.20 Mg··············· 4.50—5.50 Cr················· 0.05—0.20 Zn·················· <0.10 Be··············· <0.0003 Ti················ 0.06—0.20 Others··············· <0.05 Others Total·········· <0.15 |

|

Physical properties (Approx.Values) |

0.2% yield strength Rpo2 (Mpa)··· 110 Tensile Strength Rm (Mpa)····· 240 Elongation A5 (L0=5d0) (%)···· 17 Test Temperature (℃)····· 20 |

|

Performance & Usage |

This type of pwireuct is widely used in general welding material with the Mg of 5%, which can be used in jointing or overlay forging and casting alloys processing. And the pwireuct is of high toughness , good forgeability, and well anti-comosiveness. |

| Shielding gas | Argon, Helium, or Argon/Helium—mixtures. |

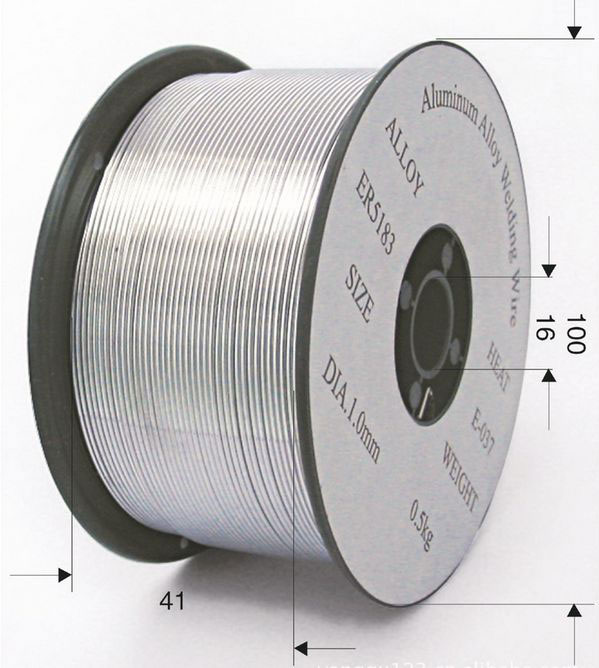

| Dimensions Φ |

MIG—wires (mm): 0.8 ; 0.9 ; 1.0 ; 1.2 ; 1.6 ; 2.0 ; 2.4 TIG —wires(mm): 1.6 ; 2.0 ; 2.4 ; 3.2 ; 4.0 ; 5.0 ; 6.0 |

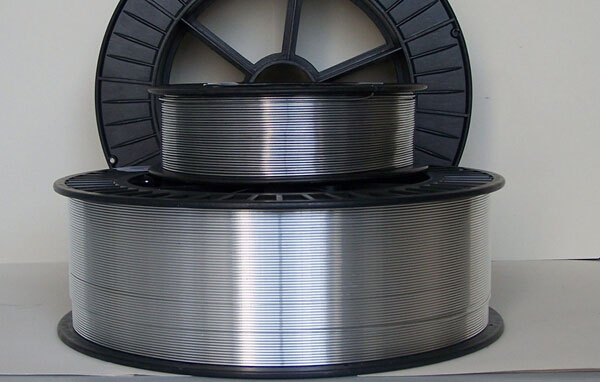

| wire Packagings |

Mig wires : S100/0.5kg 1Lb , S200/2kg , S270-S300/6kg-7kg |

|

Tig wire : 5/10kg ······· length :1000mm |

|