Aluminum alloy I beam can be used for hull construction, with light weight, high strength, good corrosion resistance, the number of turnover, high residual value.

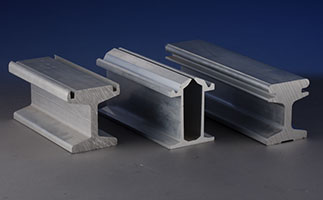

aluminum alloy I beam including the upper wing, lower wing, web, web respectively, with the upper wing, the lower wing fixedly connected.

Aluminum I beam for ships mechanics: a beam is placed horizontally on both supports and the beam is bent when the beam is subjected to downward pressure perpendicular to the axis. In the upper part of the beam compression deformation occurs, that is, there is compressive stress, the closer the compression of the upper edge of the more serious; tensile deformation occurred in the lower part of the beam, that is, tensile stress, the closer the lower edge of the more serious stretch. The middle layer neither stretch nor compression, so no stress, usually called the neutral layer. Due to the contribution of the neutral layer to bending is very small, so often used in engineering instead of square beam I beam, hollow tube instead of solid column.

Marine grade aluminum i beam alloy models include 5083,5086,6061,6082, etc., commonly used is 6061 aluminum alloy I beam.