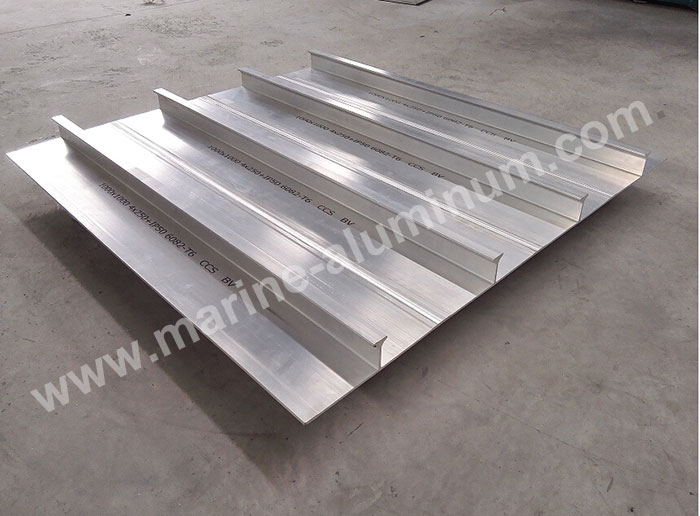

The marine grade aluminum ribbed plate is a plane structure with several parallel shapes in one direction. The application of

marine aluminum ribbed plate shows obvious advantages in structure performance, hull quality and construction period, and improves the performance of the ship structure.

1.geometric accuracy of

marine grade aluminum ribbed sheet structures

This is because the section of the component and its positioning are determined by the extrusion die, rather than the traditional plate by manual welding. As a result, the marine aluminum ribbed plate is close to "geometric plane", which is the overall stability and local stability of marine aluminum ribbed sheet, which exceeds the traditional plate.

2.the residual stress in the aluminum ribbed plate structure is very small

The residual stresses in aluminum extruded profiles are generally very small (less than 20Mpa), from the practical point of view, the influence on the carrying capacity can be neglected. The compressive residual stress at the edge of the welded aluminum alloy profile is about 20% of the baseline stress. It can be seen that the

marine aluminium ribbed plate is improved both in construction and in service.

3.The marine grade aluminum ribbed plate makes the structure weld less

A large number of welds are not used to connect the common longitudinal sections with aluminum ribbed plate, thus shortening the construction period of the aluminum alloy hull structures.